Revived tabletops

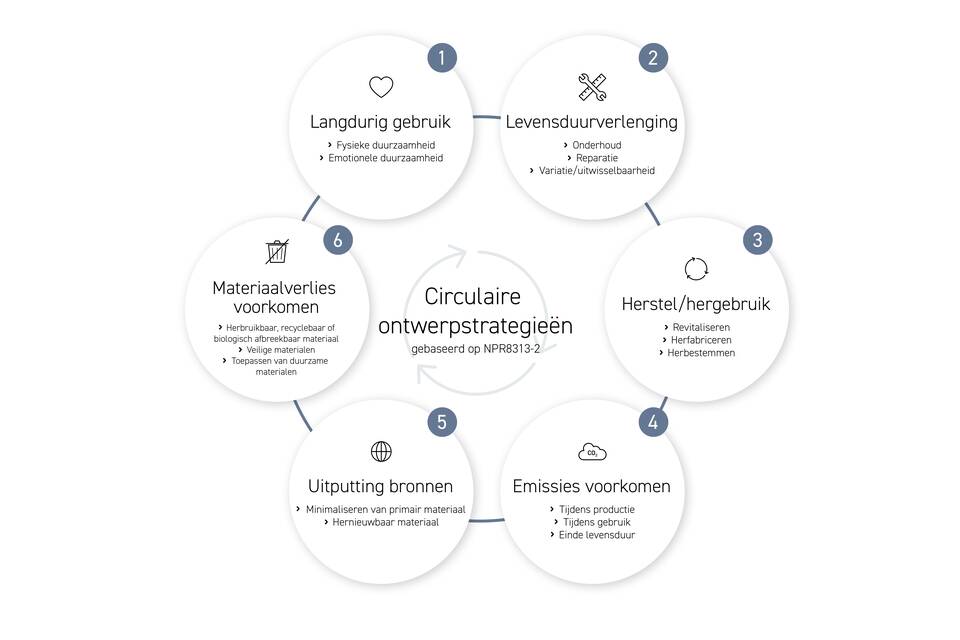

Renewable and reusable materials are the key to a climate-neutral future. This is why the circular philosophy is at the heart of all our products. By doing so, we prevents raw materials from becoming waste and we (re)uses parts and materials for as long as possible. This includes our Revived tabletops. How we do this? Our Materialisation Product Manager Lizzy Stuyfzand explains.

Reducing waste

45% of all CO2 emissions come from the production of materials.* However, the resources we have on earth are limited. That’s why we are building a circular system in which we waste as little as possible and in which old materials are turned into new raw materials. Lizzy Stuyfzand, Materialisation Product Manager, focuses on material innovations: "Currently, 85% of our tabletops are made from recyclable material. For example, our particleboard MFC is 100% recyclable, and it consists of 100% residual wood.** Revived tabletops preserve more of the product’s value, by reusing them rather than recycling them."

*Ellen MacArthur Foundation, Closing the Gap (2019) and Global Alliance for Buildings and Construction, Global Status Report (2021)

** About 50% of residual wood is from post-consumer wood, 35% from pre-consumer wood, and 15% from industry and residual wood from sustainably managed forests according to PEFC (trademark licence number CU-PEFC-COC-808416).

Compact tabletops

Lizzy: "Every year, about 5,000 tabletops made of Compact material - formerly known as Ciranol - return to the Circular Hub. These robust tabletops have a technical lifespan of up to 30 years. The technical service life of our products is often many times longer than the average service life of office furniture, which is often only 8 to 10 years. As a result, maximum value is not extracted from the material, resulting in a high percentage of material loss. With Revived tabletops, we want to contribute to reducing waste and eliminating waste, while maintaining quality and functionality.

5.000

We revitalise tabletops annually in the Circular Hub

90%*

CO2 savings Revived versus new

45%**

of all CO2 emissions come from production of materials

Revived tabletops

To promote value retention and extend service life, Ahrend has come up with a solution: Revived tabletops. Lizzy: "Based on our LCA calculations, we can show that we can achieve 95% CO2 savings compared to the production of a new Compact tabletop. To make this possible, we have developed a 100% circular chain. In this, we are frontrunners. On our way to a climate-neutral future, we are not only looking at CO2 reduction, but also at extending the life of products and reducing waste."

How does it work?

"After the end of their useful economic life of about 10 years, the Compact tabletops return to the Circular Hub. That's about 5,000 a year. There, they get a quality check to see if they can be repaired. If they pass this selection, they will then be transported to a local company that will provide them with a new top layer. The tabletop is now ready for its next life. By repeating this process, we preserve the value of the product and extend its lifespan."

‘On our way to a climate-neutral future, we are not only looking at CO2 reduction, but also at extending the life of products and reducing waste.’

The benefits for you

- You contribute to CO2 reduction with your table or desk

- You get a 'like new' product, without putting extra strain on the environment

- You can choose a Revived tabletop for different bases

*The percentages and dates named in this blog are calculated according to the LCA method, in accordance with to ISO 14025 and ISO 15804

**Ellen MacArthur Foundation, Closing the Gap (2019) and Global Alliance for Buildings and Construction, Global Status Report (2021)

We are happy to work together with you!

Want to know more about our Revived tabletops or have a question? We are happy to help you with this.

Contact us